Up until the mid 19th century all the nails used were either forged or cut, that is either heated in a forge and then shaped, or sheared off of strip stock and upset at one end to form a head. These styles of nails largely disappeared during the late 19th century as cheaper nails made from steel wire took over. Up until the mid 19th century all the nails used were either forged or cut, that is either heated in a forge and then shaped, or sheared off of strip stock and upset at one end to form a head. These styles of nails largely disappeared during the late 19th century as cheaper nails made from steel wire took over.

Cut nails however, grip better than wire nails for a bunch of reasons.

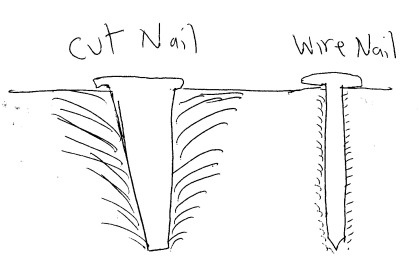

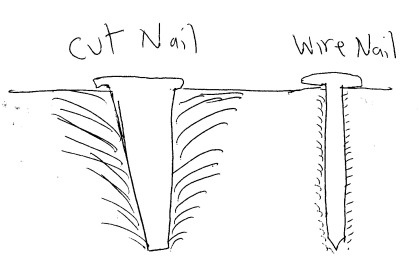

1 - Nails hold in place for the same reason Japanese plane irons keep position. When you bang in a nail you push the fibers of wood down. After nailing, in order for the nail to pop out the nail has to overcome the force of thousands of wood fibers acting like little barbs that grip the nail (fig 1). Wire nails are round and only taper at the tip, so the wood fibers along the shaft of the nail are only bent a little. With cut nails, which are tapered throughout their length, the taper increases as the nail goes deeper so more and more wood is bent away with increasing force resisting pullout.

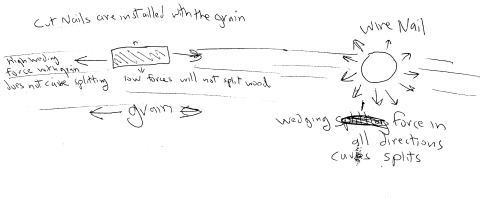

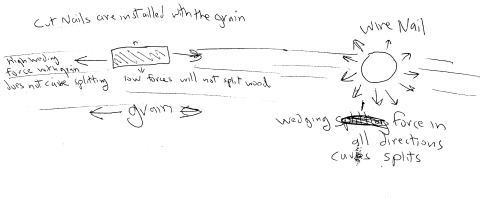

2 - More wedging action all around also mean more forces that can split the wood. When you hammer in a wire nail the pointed tip wedges the wood in all directions. A large wire nail will have more force holding it in than a small wire nail, but also more force trying to split the wood. Cut nails are only tapered in one dimension and when installed properly with the wedge parallel to the grain of the wood, the taper of the nail is with the grain so it doesn't force a split, and the parallel sides of the nail won't cause a wedging action that would split the wood. So, for a given size and length of nail you get a lot lot more holding power with a cut nail.

3 - The wedging action of a wire nail is fixed by the diameter of the point. Far more wedging action can be achieved in the continuous increasing taper of a cut nail. Some cut nails (boat nails) have a wider section in the middle so that the wood at the top of the nail can swell back around the nail for even more strength. 3 - The wedging action of a wire nail is fixed by the diameter of the point. Far more wedging action can be achieved in the continuous increasing taper of a cut nail. Some cut nails (boat nails) have a wider section in the middle so that the wood at the top of the nail can swell back around the nail for even more strength.

4 - The square section of a cut nail resists attempts at twisting the wood which is easy to do with a round wire nail. This reduced movement helps keep the nailed structure stable.

5 - A cut tail is tapered top to bottom so that the top piece being nailed down is held down by the taper of the nail and you don't need much of a nail head. This allows for a much smaller nail head that is easily set flush with the wood. With a wire nail, with less gripping force, the head is an important part of keeping the joint from separating with a more visible result.

6 - While not related to holding power the tops of cut brads are smooth and don't deflect away from the hammer blow as much as the pinched top of a wire brad. So the cut nail is more reliably easily nailed in.

Where do you get cut nails? Funny you should ask that. Take a visit to our new nail salon for cut nails in small or large quantities. We are stocking a large selection of cut nails made in USA by Tremont Nail - the oldest maker of cut nails in the US. Tremont has been making cut nails since they were invented in the early 19th century. We are repacking the nails into convenient small, resealable bags. We understand that you don't always need a huge quantity of any specific type of nails so our bag sizes range from 1/8 of a pound for small finishing nails, to typically a 1/2 pound for everything else. Some of the large nails are sold by the pound. If you order 4 or more packages of any mix of nails you automatically get 10% off.

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

Up until the mid 19th century all the nails used were either forged or cut, that is either heated in a forge and then shaped, or sheared off of strip stock and upset at one end to form a head. These styles of nails largely disappeared during the late 19th century as cheaper nails made from steel wire took over.

Up until the mid 19th century all the nails used were either forged or cut, that is either heated in a forge and then shaped, or sheared off of strip stock and upset at one end to form a head. These styles of nails largely disappeared during the late 19th century as cheaper nails made from steel wire took over.  3 - The wedging action of a wire nail is fixed by the diameter of the point. Far more wedging action can be achieved in the continuous increasing taper of a cut nail. Some cut nails (

3 - The wedging action of a wire nail is fixed by the diameter of the point. Far more wedging action can be achieved in the continuous increasing taper of a cut nail. Some cut nails (

And eggbeater drills are the next passe tool. I predict a flurry of bow-drill blog posts in 2012.

I like to have a small collection of little things in the "shop" that let me proceed on projects without thinking about gathering much more than the wood. It took me a while to figure out what were good sizes of screws to have around for projects around the house and shop.

Do have any suggestions of what types/sizes of nails to pick up to have a decent assortment for different projects?

http://lostartpress.wordpress.com/2009/03/22/clinching-nails-sometimes-teeth/

It has been said that the blunt tip of cut nails rend to crush fibers downward instead of forcing them outward. This is another reason that splitting is reduced. I believe his to be true because of experience. My grandfather taught me to always flatten the sharp point of nails with a hammer tap. This may be nothing more than superstition, but I rarely ever have wood split with a flat tipped round nail.

Regressing to an air powered brad nailer, which has flat ends, is the way to go when a lot of work needs to get done fast. Teaching the students how to use the pneumatic brad nailer was quick and probably safer than a hammer in inexperienced hands.